Timing belt replacement – Lotus Excel SE (1986 with round

tooth belt and eccentric tensioner)

I have updated this after changing my cambelt. So you know it can be

done!

Click on the pictures to get a bigger version.

If anyone has any comments/suggestions please email

me: steve at benani dot com

1. Disconnect battery - just for safety.

Remove bonnet – undo & remove bonnet

earth strap, windscreen washer pipe, disconnect gas strut, undo

locknuts (10mm), withdraw

(using M4 Allen) M8 x 50 pins.

* On my

car the 'bolts' are 8mm

and need a 13mm spanner to undo the lock nut and a 4mm allen

key

to remove.

I would recommend a 1/4

drive ratchet as they are quite long!

Now you can get at everything so much easier.

*Cover wings and front panel with cloths

to protect

paintwork. I always put a good coating of

polish and

don't wipe it

off then cover with old towls.

2. Remove air inlet trunk (flat screw on

jubilee clip and cut securing cable ties).

3. Remove upper and lower timing belt

covers –

undo twist lock fittings 90° and withdraw carefully. Remove

belt

cover supports where fitted. Turn the engine by hand in neutral so that

you have a ‘feel’ for resistance. If needed,

slacken /

remove spark plugs for easier turning.

* Top

belt cover has throttle

cable held to it by a clip, just pull the cable out. I would recommend

removing the spark plugs it make it so much easier to

turn the

engine over by hand.

4. Align timing marks – Cam

pulleys, crank

pulley (TDC), auxiliary pulley for ignition timing and highlight with

Tippex / white paint. Count and record numbers of belt teeth between

marks – e.g. crank pulley mark to auxiliary pulley mark

(preferably between all marks for completeness). Note –

additional reference marks can be painted on as required. Fit a double

cam pulley holding tool to lock the cams in place or make sure you have

clear alignment marks for the cams.

Cam pulley

marks

TDC marks

Ignition

pulley

mark*

4a. Another

suggestion for aligning the timing marks. Paint a sort of

wide stripe across the

edge of the belt to include two adjacent teeth. Now, here's the

important part; continue the paint across the edge of the cam pulley as

well. The inlet pulley is probably easiest.

For the other reference marks, paint a single stripe across all other

pulleys AND belt.

This method establishes the all important relationship between belt

and pulleys. It eliminates the need to count teeth, and you don't need

to bring the engine to TDC.

With the old belt removed, transfer all markings to the new belt and

install.

4b. Another method that has been

suggested is to cut

the old belt to leave about a 1/4 inch of belt on the car then fit the

new belt. When you have the new belt 3/4 way on cut and remove the old

belt. Using this method I would suggest that you are very, very careful

how much you slacken off the tensioner, to much and the ignition pulley

will be able to 'slip' a tooth on the old belt.

* As you can see from the above picture

on my car

the ignition pulley mark was not in the position that many websites say

it should be. This does

not matter.

The only thing that matters is that you do not move the pulley.

CAUTION: The

ignition pulley will move very easily. Take a picture, as above, before

you remove the old belt.

5. Remove lower coolant hose and drain

1-2 litres of

coolant. NB ensure that heater flap is fully open inside car (HOT

setting). Collect coolant for re-use if required.

6. Check the installed tension of the

v-drive belts

for reference when installing new items. Slacken the adjuster and

remove the v-belt from the alternator. Slacken the bolts and remove

v-belt from power steering pump.

* PAS pump is slackened by the 2 allen

bolts (8mm allen key).

7. With engine in gear (e.g. 4th) slacken

retaining

bolt on crankshaft v-pulley in preparation for later removal (access to

cam belt tensioner). If the bolt is done up tight, use a large

screwdriver inserted through hole in transmission casing at lower

driver’s side (RH drive) of engine into starter ring gear to

lock

up the engine while the pulley bolt is unfastened –

don’t

forget to remove this afterwards!

8. Re-position engine if necessary to

ensure cam

pulleys, crank pulley and aux pulley are at timing marks. Ensure the

engine is in gear/transmission locked and lock the cam pulleys in place

using clamps if you can (or borrow a friend to help keep their

alignment). CARE – engine must not rotate from this point on

in

order to avoid bent valves!!

9. Remove top radiator hose and any other

pipework needed to access the cam belt /tensioner, etcetera.

10. Remove the crank v-pulley to access

the eccentric

tensioner. This can be difficult and may require a pulling tool

–

there is not much room between the pulley and oil cooler. Slacken the

cam belt tensioner bolt and note the orientation of the tensioner for

re-installation (it can be adjusted eccentrically in two directions and

only one is correct – with the eccentric hole towards the

top).

Remove the tensioner and install a new bearing, pressing off the old

one in a vice.

Crank

pulley

off

Tensioner

loose

11. Remove the cam belt and carefully

replace with a

new item, checking for correct orientation, exact match (size, tooth

profile and number of teeth) and ensuring same relative position

– i.e. same number of teeth between key marks (crank

pulley/aux

pulley, exhaust pulley/crank, etc) as originally.

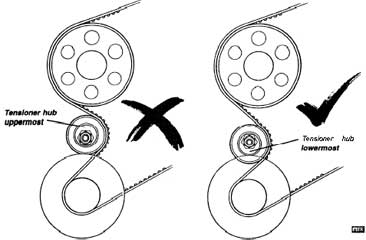

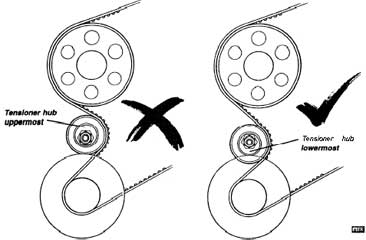

12. Re-install the tensioner and adjust

it to tension

the new cam belt. Note that the eccentric adjuster can swing against

the belt in two different directions and should be installed so that

tension tightens the bolt, i.e. by swinging anticlockwise as

viewed

from engine front. Tension is correct when there is nominally

85-90° of finger twist about a vertical axis between the aux

and

inlet cam pulleys. Check that all the timing marks still align

–

ESPECIALLY ignition timing - and correct any if needed.

How the tensioner should be.

I found the above picture on the internet, can't

remember,

where so if the owner would contact me I will credit them or remove it.

13. If timing marks are correctly

aligned, remove the

cam pulley clamps and place the transmission in neutral (or remove

screwdriver). Replace the crank v-pulley if needed for the alignment

check and tighten its bolt firmly. Turn the engine clockwise by hand

gently and check the belt tension at 1/3 turn intervals for at least 2

full revolutions. If excess resistance is encountered return the engine

in the reverse direction to TDC and re-check timing mark alignments.

Check for mis-alignment of the belt on the pulleys. ENSURE that the

tensioner is correctly tightened – if this slips, the damage

caused can be considerable.

14. If alignments are correct and the

tension

acceptable, replace the crank v-pulley (if not done already) and

re-install or replace v-belts. Ensure that V belts are correctly

tensioned (i.e. pretty tight). While you are down there, check that the

bolts holding the PAS pump are secure – if not, remedy this

promptly as it can cause expensive problems later.

* My PAS

pump bracket was loose

and one bolt was missing. They are very difficult to get at but it is a

must do job.

Two allen bolts at the front which you can't see use 6mm

allen

key, the two nuts at the back are 13mm spanner size.

15. Replace the coolant hoses, check that

they seal

well and replenish the coolant. If using new coolant, check that the

anti-freeze is alloy compatible and dilute (1:1) with de-ionised water.

Re-install / tighten spark plugs if they were loosened or removed.

16. Replace the lower and then upper

timing belt

guards. Ensure that the timing belt passes them freely when turned by

hand (i.e. no fouling or abrasion).

17. Start the engine (carefully) and

listen to the

cam belt. If there is excessive noise the belt tension is a probable

cause and will need to be re-checked. Basically an over-tight belt will

whine and a slack belt will flap or flutter on over-run. Let the engine

run for ~ 2 mins. Stop the engine and re-check belt tension. Also check

for minor coolant leaks from the hose unions and tighten them if

needed. If all is OK, replace the other components – air

inlet

hose (cable tie this in place in its brackets), bonnet and so forth.

18. Check for missing / loose components,

stray tools

and top up the coolant. Tidy away other materials. Job done.

Original written by chrisw2811

with additions by GavinTaylor

& myself.

Find us and a lot more very helpfull folk at the

excellent Lotus

Excel forum

NB. The usual disclaimers apply - ie if it goes wrong you can't blame

anyone but yourself.

...................................................................................................................................